Managing Legacy Components in Industrial Computing

Posted on December 2, 2024

Chances are that your business still uses computers with legacy components – ie. old, superseded technologies that nevertheless still get the job done. How do you deal with legacy systems without negatively impacting your operations?

What Exactly is a “Legacy” Component?

Computer technology evolves at a breakneck pace. Standards that are cutting edge right now will be replaced by something better in a few years, with new hardware to match.

But that does not mean the older technology is unusable. The new tech brings better performance, true, but the legacy systems still work, and often the tradeoff involved in upgrading a large setup is not worth the performance boost it brings.

This leads to many businesses continue relying on their legacy systems way past their expected lifecycle, at which point the new products coming into the market no longer support the old technologies.

Examples of such technologies are numerous: standards like IDE, VGA, ISA, Parallel Ports, etc. All of these have been superseded by better technologies but are still widely in use.

Are Legacy Systems a Problem?

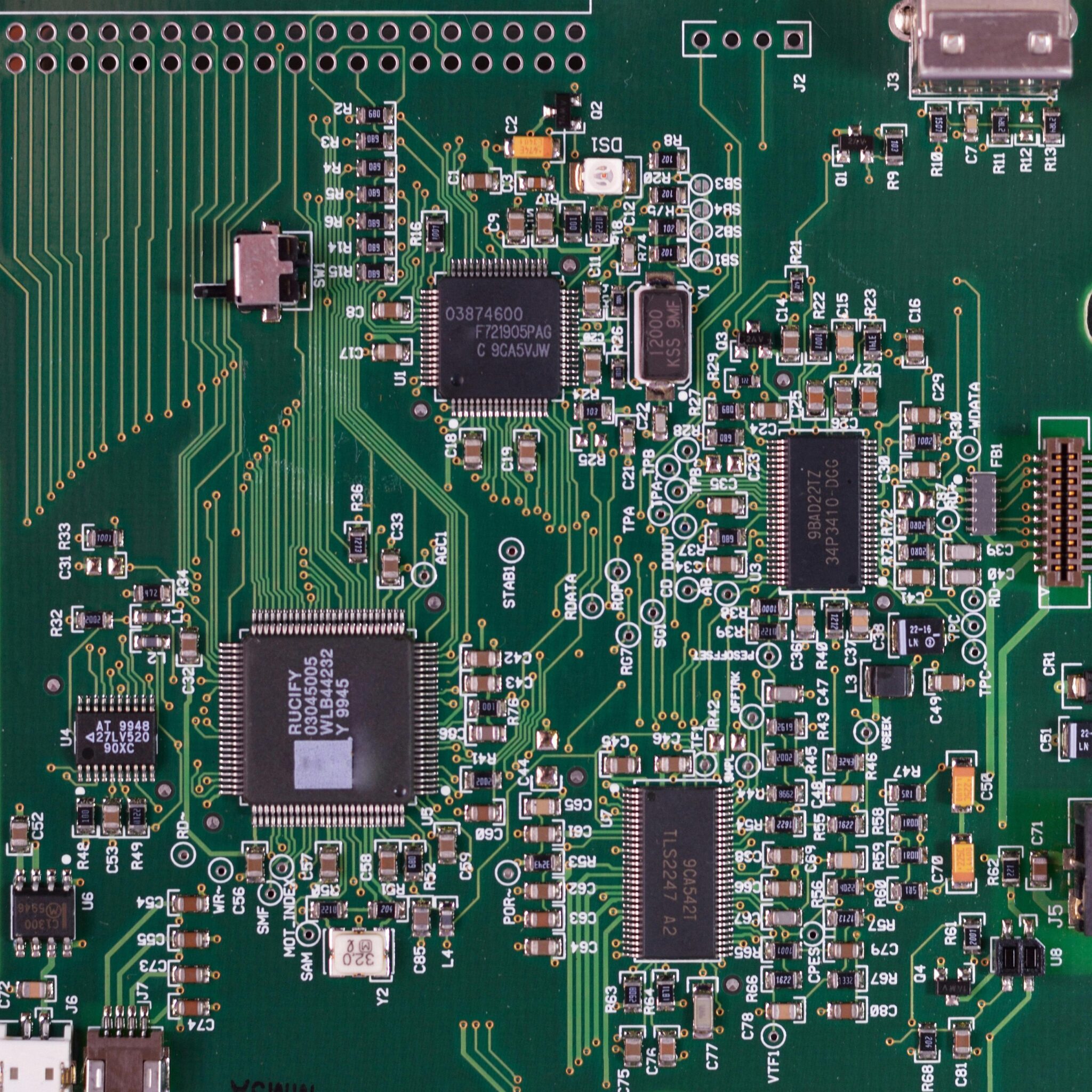

Industrial computing is one of the few places where legacy technologies are still in use, rubbing shoulders with the latest products within the same ecosystem. But that can also be a problem.

Legacy components aren’t actively supported by their manufacturers, making it tricky to deal with repairs and breakdowns. Not to mention compatibility issues with newer tech as you upgrade the rest of your setup in stages.

Then there is the performance cost – as a rule of thumb your legacy system will be outperformed by newer models, and this gap only widens with time.

That being said, a well-managed legacy framework can continue supporting you long past its official expiration date, as long as you know what you are doing.

Managing Legacy Components in Industrial Settings

The key to getting the most out of your legacy systems while not suffering any slowdown or losses is to understand the limits of the system and match it with the right application. For example, if you have a variety of machines controlled through an embedded PC with parallel ports, you can upgrade this controller to boost its responsiveness and integrate better with the rest of your framework without having to throw out the peripherals.

And yes, most leading providers offer computers with legacy ports for this very reason. The idea is to minimize your upgrade expenses while also keeping up with the advantages offered by newer technologies.

In some cases, it may even be possible to upgrade the older computers as well with extension cards, though this is only suitable when the application’s needs are adequately fulfilled by that system.

How Important is it to Upgrade Your Legacy Systems?

Embedded and industrial systems are designed with longer lifecycles in mind than a home PC – you can expect to see your investment support you for years. As such, it is common to have your systems be outpaced by innovation even before reaching the end of their lifecycle.

This does not mean that you need to keep upgrading your setup every few months; throwing out a perfectly functioning system for every incremental change is pointless.

The ideal approach is to use your setup through its complete lifecycle, phasing them out for new systems at the end. This gives you value for your investment while ensuring you keep up with upgrades without having to deal with defunct equipment.

If you continue using a legacy system past its official lifecycle, things start getting a bit more difficult, because at that point the manufacturer no longer supports the product. Which means that you need to look for resellers and other providers to supply you with replacement parts from remaining inventory.

So Are Legacy Components a Problem?

Not entirely. Most modern day industrial computers also come with older ports like ISA, IDE, or DVI, letting you continue using your legacy machines while upgrading critical PCs to get a performance boost.

Processors are the trickiest component to manage like this since a newer chip cannot be slotted into an older socket, though you might be able to procure the same CPU from a seller’s remaining inventory.

As figuring out which parts of your setup need a rehaul can be hard, it is best to take the advice of an embedded systems provider. Here at Global American, for example, we go through our clients’ current setup and needs, providing legacy compatible systems to ensure they are able to get the most out of their existing technology.